This website uses cookies to ensure you get the best experience on our website. Learn more

You get 20% off on your first purchase

Sign up for our newsletter, stay in the loop with exclusive deals, updates, and more!

Get 20% off

You get 20% off on your first purchase

Sign up for our newsletter, stay in the loop with exclusive deals, updates, and more!

Get 20% off

Have you ever seen the footwear manufacturing process? From beginning to end, there are several steps taken. Let us take you thru each one!

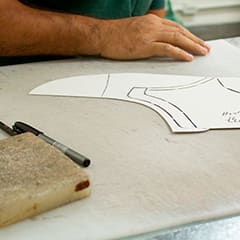

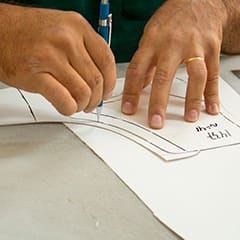

The first stage of shoe making begins in the development room. That is where our design team delivers the technical file containing all the information obtained thru their development and research. Once there, this file passes onto the hands of the pattern maker, who will sketch the shoe onto the last. From this sketch, we will have what we call the “shoe standard”, which is a two-dimensional spread of the last’s shape, allowing a 2D drawing to be turned into a three-dimensional puzzle.

This is where all the materials, present in the technical file, are sorted and prepared. The type of synthetic or fabric that will be used, metals, laces, insoles, etc. Our team inspects the quality of each item, before sending them to the production team.

Once the necessary materials are sorted and verified, they are taken to cutting. At Ahimsa, cutting can be done by a automated machine or through an old-school manual process. In this sector, we cut all the pieces that the pattern maker drew from the last. After being cut, the pieces are taken to the skiving sector – which is where the cutted pieces are made to have uniform thicknesses.

At stitching, the pieces are joined to form the upper, which is what we call the external area of the shoe. In a group usually made of 3 people, we make the necessary folds and add glue, to secure the parts until they can be joined by the stitching threads.

As the production of the upper advances thru stitching, the outsole manufacturing takes place on a separate sector. Our team of outsole makers adds several pieces of sheeted rubber together, making a sandwich, that will later form the entire outsole

It is in this step, between stitching and assembly, our team will match all the other materials sorted in the raw materials inventory room, with the finished upper and outsole, so the footwear can advance to assembly.

This is a three-step process: first we wrap the upper over the last and prepare it to have the outsole attached to it. This is done by a mounting machine, that handles much of the process automatically. Glue is added to adhere the toe region of the upper to the mounting-insole, holding the last’s base design. On step-two, the sides of the footwear are closed, and on step-three the heel area is closed as well. Both of this steps are also assisted by machines.

At the finishing sector, we take take the final steps to make sure that the shoe is even more beautiful. In the uppers containing parts of Vegan Leather, we use carnauba wax, which polishes the shoe, giving it shine, smothiness and adding durability to the material. After that, the shoe it is ready to receive the outsole

Finally, the shoe is prepared for packaging. Insoles and laces are added, and the shoe proceeds to be quality checked and packaged. Once all details are verified, our team tidys everything by adding the shoe bag to the box, and finishes by placing a letter signed by our entire team.